Scientists from the University of Leicester in the UK have discovered a process to recover silver and aluminum from used PV cells that is cheaper and more environmentally friendly than current recycling processes using mineral acids.

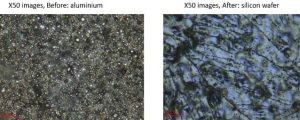

Images of the solar cell before the process (left side, aluminum), and after (right side, silicon wafer).

Image: University of Leicester

The researchers used the technology on crystalline solar cells measuring 12 × 15 cm, weighing 2 g, and consisting of a 100 ?m thick silicon wafer, coated with a 100 nm thick silicon nitride anti-reflective layer on the front side and a 20 ?m thick layer of aluminum on the back side, both stripped with silver electrodes approximately 30 μm high.

“First, we place the solar cell in an aluminum chloride solution. The aluminum electrode is removed from the silicon wafer. We use ultrasound to promote the dissolution of the aluminum, which takes place within a few minutes,” researcher Guillaume Zante told pv magazine.

Given the low cost of aluminum, there may be no economic interest in recovering it, but the aluminum salt solution could be used for wastewater treatment purposes, according to the scientists. “In the second step, the silver is dissolved from the solar cell using iron chloride, an oxidizing agent, in a choline chloride or calcium chloride brine, which takes around 10 minutes,” Zante explained, noting that the components of these two brines, or salt water, are found in chicken feed and grit used on roads to avoid ice, respectively, and are thus widely available, cheap, and low on toxicity.

“It is interesting to note that iron dissolved in water cannot oxidize silver, but iron dissolved in the brine can. Using a brine instead of water improves the ability of iron to oxidize silver and improves the solubility of silver in the brine,” Zante said. “This is due to the presence of chloride ions in the brine. The addition of water to the brine dilutes the chloride ions, allowing the silver chloride to precipitate. Silver chloride is easily filtered from the solution.”

This process successfully recovers silver chloride with a purity of 98%, which according to the researchers could be converted into metallic silver in a further step, thereby increasing its purity. The process does not affect the silicon wafer and nitride anti-reflective coating, leaving open the possibility to reuse the silicon in PV panels or processing it for other uses.

The results were obtained in a lab setting, using a few grams of solar cells, and may differ at an industrial scale. However, the authors believe that industrialization is feasible due to their use of cheap, low-toxicity and readily available chemicals. “Since we are using cheap chemicals, the price could be as low as the processing costs with mineral acids and in some cases cheaper, around $0.4 lower per kilogram of solar cell as compared to mineral acids,” Zante affirmed.

They presented their findings in “Efficient recycling of metals from solar cells using catalytic etchants,” which was recently published in the Journal of Cleaner Production. The scientists are currently developing a strategy to scale up the technology and to extract other metals from waste sources, including bismuth, tellurium and copper from thermoelectric materials, which are used in perovskite, thin film, and wiring and cabling in solar cells, respectively. They are also attempting to extract gold, nickel and copper from printed circuit-boards, as well as neodymium and dysprosium from waste magnets. The academics are part of the Met4Tech project, which supports the creation of a circular economy for technology metals.