Domestic solar module manufacturers are slowly ramping up capacities to supply India’s solar project pipeline of over 53 GW and another 24.1 GW of projects tendered and pending auctions as of Q1 2021.

Solar module manufacturer Premier Energies has recently announced a solar photovoltaic (PV) module manufacturing facility at E-city, Hyderabad, to increase its module production capacity.

Mercom spoke with Chiranjeev Saluja, Managing Director of Premier Energies, to discuss the company’s plans and his thoughts on the existing policies related to the solar sector.

What is the new manufacturing capacity that Premier Energies has added, and what is the new total capacity now?

Our manufacturing facility in Hyderabad has 750 MW each of solar modules and solar cells manufacturing capacity. With this, the company has a cumulative module manufacturing capacity of 1.25 GW and 750 MW of solar cell manufacturing capacity. The company also plans to increase its capacity by 2 GW over the next two years.

How much capital was invested in this manufacturing facility?

The new capacity has been built with an investment of ?4.83 billion (~$65.14 million). With this new facility, Premier Energies will likely be amongst the top five solar module manufacturers in the country.

Is the new manufacturing capacity fully operational?

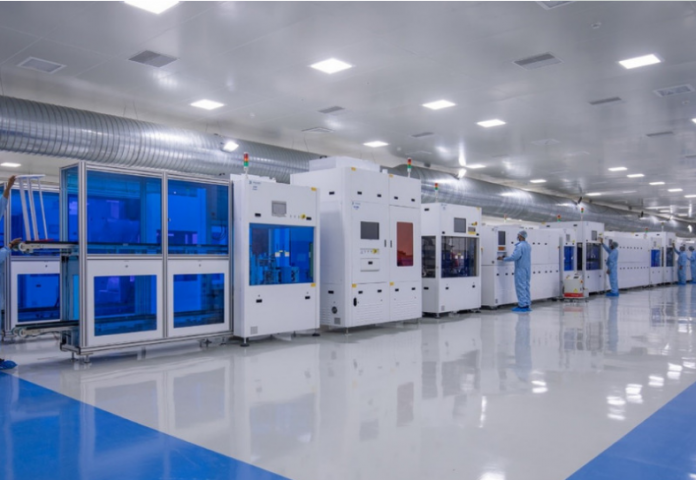

Yes, the new manufacturing facility is fully operational. The facility can manufacture the latest metal catalyst chemical etching textured multi-crystalline cells, mono passivated emitter, and rear cells (PERC), while the module making facility is capable of producing the latest multi busbar half-cut and bifacial modules.

What is the technology used in the new manufacturing capacity?

The new facility has a fully automated solar cell manufacturing line with mono PERC and multi-crystalline cell technologies. The line can handle wafer sizes from 156 mm to 210 mm. The module manufacturing line produces half-cut and bifacial modules.

The facility has quality control systems like total quality control and statistical process control, and the facility is certified with ISO 9001/ ISO 14001.

What was the driving factor behind this manufacturing capacity expansion?

Working towards a greener decade while contributing to India’s power sector is the motivating force behind Premier Energies. Solar energy has proven to be a viable alternative to traditional energy and a viable solution to India’s power crisis, particularly in villages, over the last few decades. Solar energy has a crucial function in irrigation and harvesting in an agricultural economy like India.

By increasing our capacity with this new facility, we will be able to contribute to India’s growth story. Also, this launch will increase the availability of the highest quality of ‘Made in India’ solar cells aligned to the government’s Atmanirbhar Bharat initiatives.

What was the reason behind building the facility in Telangana?

Telangana government was proactive in giving us the right incentives to set up the facility and provide quality water and power, which are critical for solar cell manufacturing. That said, Premier Energies has a 500 MW operational manufacturing facility in Hyderabad that helps provide access to a trained and qualified workforce, which is critical for a new facility.

Are you expecting all the demand to come from domestic markets, or are you also planning to expand export activity?

Currently, the domestic demand is quite good due to the domestic content requirement market and impending customs duty on imported modules and cells. However, we would like to have a sales spread and plan to export to North America and European markets. This would also drive us to increase productivity and compete with international players.

Do you plan to vertically integrate into cells and wafers?

Currently, the facility is integrated for manufacturing both cells and modules. We are evaluating the manufacturing of wafers, which requires the right incentives to make its production in India viable.

Premier Energies to Make Half-Cut and Bifacial Modules at its New Facility

The company will also produce mono PERC and multi-crystalline solar cells at the unit

Source:MERCOM

ViaHarsh Shukla